Choosing a logistics partner can make or break your brand’s growth. If you’re asking, “What is a third-party fulfillment service?”, you’ve come to the right place. This guide explains exactly what a 3PL does, how a fulfillment center works, and what capabilities matter most when you sell across multiple channels. We’ll move beyond simple definitions to give you practical advice for choosing the right partner. You’ll learn how to match services to your sales channels, demand the right technology, understand pricing, and recognize when it’s time to outsource. Let’s dive into how fulfillment can become a true extension of your brand.

Key Takeaways

- Define 3PL Clearly: A third-party logistics (3PL) partner handles your physical fulfillment, from receiving inventory to managing returns. They provide the warehouse, labor, and technology so you can focus on growing your business.

- Map Services to Needs: Evaluate providers on their ability to handle your specific sales channels, like direct-to-consumer (DTC) picking, retail-compliant B2B prep, and custom kitting. A single, capable 3PL prevents operational headaches.

- Prioritize Technology & KPIs: Insist on key integrations (like Shopify, Amazon, and EDI) for real-time inventory visibility. Use Key Performance Indicators (KPIs) like order accuracy and on-time shipping to measure success and ensure accountability.

- Understand the Costs: Budget for clear pricing drivers, including storage, pick/pack fees, and value-added services. Outsource when order volume, cross-border shipping, or retail rules become too complex to manage in-house.

- Find the Right Fit: For North American expansion, a regional mid-market 3PL might offer better Canada-U.S. shipping strategies than a global giant. Focus on partners who can blend DTC and B2B fulfillment seamlessly.

What Is a Third-Party Fulfillment Service (3PL)?

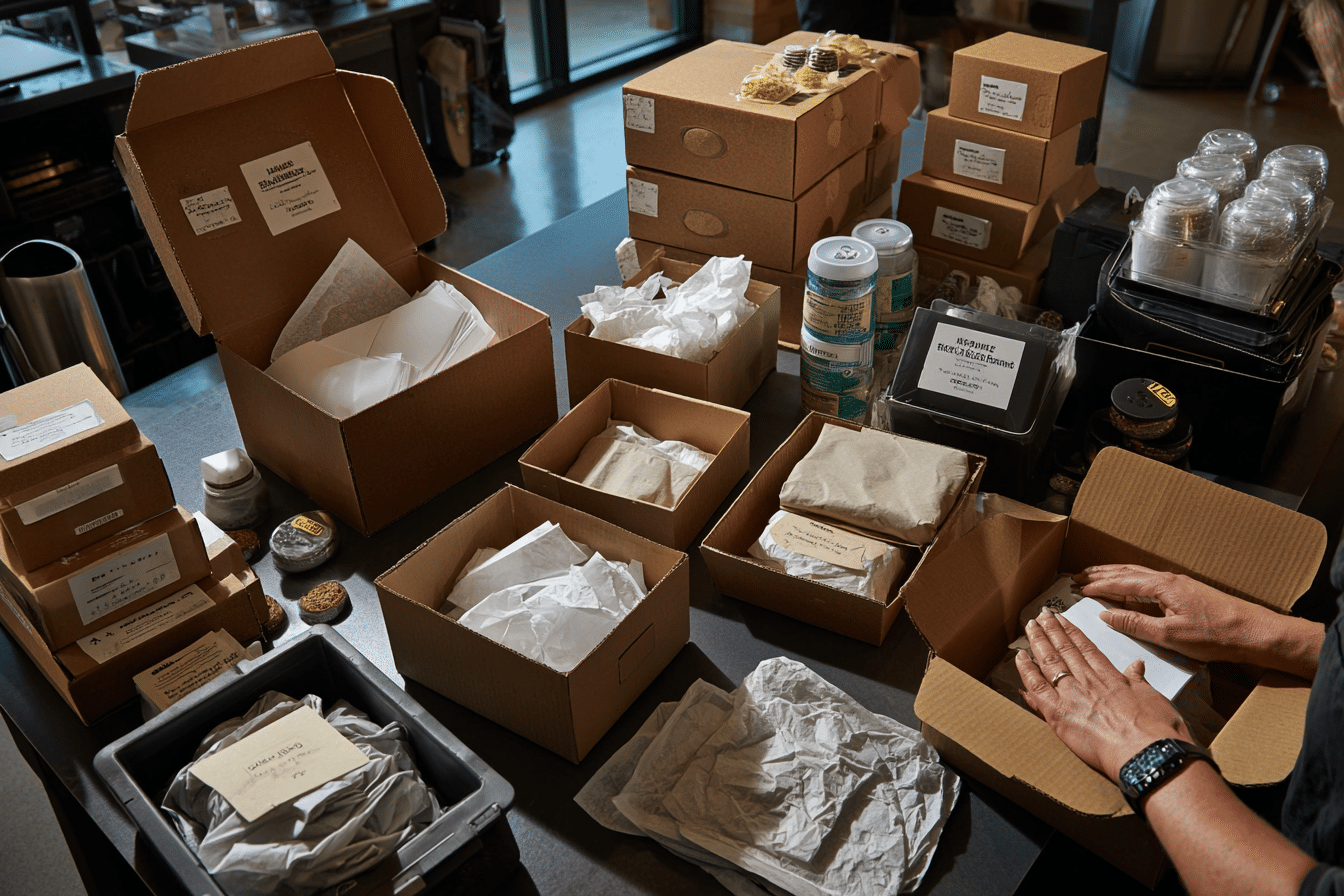

Q: What is a third-party fulfillment service? A:_ A third-party fulfillment service, or 3PL, is an outsourced partner that manages your order fulfillment operations. This includes receiving and storing your inventory, picking and packing orders, shipping them to customers, and handling returns._ Think of a 3PL as your brand’s operational backbone. You own the products and the customer relationships; the 3PL owns the logistics infrastructure. This allows you to focus on product design, marketing, and sales while they handle the complexities of getting orders out the door accurately and on time. It’s important to know how a 3PL differs from other logistics providers.

- 3PL vs. 4PL: A 3PL is a hands-on partner that physically moves your products. A 4PL (fourth-party logistics) provider is more of a strategist who might manage your entire supply chain, including coordinating with multiple 3PLs, but they don’t handle inventory themselves.

- 3PL vs. Freight Forwarder: A freight forwarder specializes in moving bulk shipments between locations, often internationally. They handle customs and book large-scale transport but don’t typically manage individual customer orders.

What Is a Fulfilment Warehouse?

Q: What is a fulfilment warehouse? A:_ A fulfillment warehouse, or fulfillment center, is a facility designed for rapid outbound order processing. Its layout and operations are optimized for picking individual items, packing them, and shipping them directly to customers, often within 24 hours._ This is different from a traditional warehouse, which is built for long-term, bulk storage. A traditional warehouse might store 500 cases of your top-selling product on a single pallet. A fulfillment center, however, strategically places those items in accessible bins so workers can quickly grab single units for customer orders. This operational focus on speed and order-level accuracy is what allows ecommerce brands to meet modern customer expectations for fast shipping.

A Deep Dive into 3PL Services

A great 3PL offers more than just storage space. Their services are designed to support your brand across every sales channel. Core Warehousing and Inventory Management Accuracy is everything. Top-tier 3PLs use warehouse management systems (WMS) to achieve over 99.7% inventory accuracy. When a shipment of your products arrives, their team receives it, inspects it, assigns it a storage location, and syncs the new stock levels across all your sales channels in real time. This prevents you from overselling products you don’t have. Order Processing: Pick, Pack, and Ship This is where a 3PL’s expertise really shines.

- For Direct-to-Consumer (DTC): They receive an order from your Shopify store, pick the items, pack them with your custom-branded materials, and ship it out—all within a tight timeframe.

- For Business-to-Business (B2B): They handle complex requirements for retail partners like Nordstrom or Saks. This includes vendor-compliant labeling, generating Advance Shipping Notices (ASNs), and meeting strict packaging rules to avoid costly chargeback fees. Value-Added Services These services adapt the fulfillment process to your unique needs.

- Kitting & Bundling: Assembling multiple SKUs into a single product for promotions or subscription boxes.

- Amazon FBA Prep: Labeling, poly-bagging, and packing products to meet Amazon’s strict FBA inbound requirements.

- Returns Management (Reverse Logistics): Inspecting returned items and deciding whether to restock, donate, or dispose of them based on your rules.

- Cross-Docking: Immediately shipping out received inventory to fill waiting orders, bypassing storage to save time and money.

The Technology That Powers Modern Fulfillment

A 3PL without a strong technology stack is just a storage unit. Modern fulfillment relies on three interconnected systems.

- Warehouse Management System (WMS): This is the brain of the warehouse, controlling all physical inventory. It optimizes pick paths for workers, tracks item locations, and manages cycle counts to ensure accuracy.

- Order Management System (OMS): The OMS is the central hub for all your orders. It routes orders to the correct warehouse, prevents overselling by reserving inventory, and provides a unified view of sales across every channel.

- Transportation Management System (TMS): This system optimizes shipping. It automatically selects the most cost-effective carrier for each package, prints labels, and tracks shipments. These systems must integrate seamlessly with your platforms, including Shopify for DTC, Amazon Seller Central, and EDI for retail partners. Real-time data syncing is not a luxury; it’s a necessity for preventing stockouts and keeping customers happy. 2025 Trends: Automation and AI Leading 3PLs are already using artificial intelligence to forecast inventory needs, helping you reorder before you run out of stock. In high-volume facilities, robotics assist with picking to improve speed and accuracy. This technology helps your 3PL partner operate more efficiently, which translates into better service and lower costs for your brand.

Understanding 3PL Pricing Models and Costs

3PL pricing is typically variable, meaning you pay for the services you use. This converts your fulfillment costs from a fixed expense (like a warehouse lease) into a variable one that scales with your sales volume. Common costs include:

- Storage: Billed per pallet or per cubic foot.

- Pick-and-Pack: A fee per order plus a fee for each item in the order.

- Receiving: A charge for processing inbound inventory.

- Value-Added Services: Fees for tasks like kitting or FBA prep.

- Surcharges: Extra fees for things like address corrections or peak season demand. Mid-market brands shipping 2,500–10,000 DTC orders monthly can expect an all-in cost of $4.50–$7.00 per order. When requesting quotes, ask for all-in pricing scenarios to avoid hidden fees.

When Should You Outsource to a 3PL?

The decision to outsource is about more than just order volume. It’s about complexity.

- Your Order Volume is Growing: If you’re shipping over 500 orders a month, the time spent packing boxes starts to outweigh the cost savings of doing it yourself.

- You’re Selling on Multiple Channels: Fulfilling DTC orders, Amazon FBA shipments, and wholesale POs at the same time is complex. A 3PL has the systems to manage this without errors.

- You Want to Expand Cross-Border: A 3PL with warehouses in both Canada and the U.S. can offer “domesticated” shipping. This cuts transit times from 7-12 days to 2-3 days and eliminates surprise duties for your customers.

- Your Team is Losing Focus: If your marketing or operations teams spend more time on logistics than on growth activities, it’s a clear sign you need to outsource. Let your team focus on what they do best.

How to Measure 3PL Success

You can’t manage what you don’t measure. Track these KPIs to ensure your 3PL is performing well.

- On-Time, In-Full (OTIF): Percentage of orders shipped on time with all the correct items. Target: 98%+.

- Order Accuracy: The rate of picking and packing errors. Target: 99.5%+.

- Dock-to-Stock Time: How quickly inbound inventory is processed and made available for sale. Target: < 24 hours.

- Cost Per Order: Your all-in fulfillment cost divided by your total orders. Your contract should include Service-Level Agreements (SLAs) that tie these KPIs to financial credits. If your partner fails to meet expectations, they should be held accountable. Q: Who is the biggest 3PL company? A:_ The title of “biggest 3PL company” often shifts based on how you measure it—whether by annual revenue, warehouse square footage, or global network size. Major global players like DHL Supply Chain, Kuehne + Nagel, and others consistently rank near the top. However, for many brands, the “best” 3PL isn’t the biggest. It’s the one whose services, locations, and expertise best align with your specific needs._

Benefits vs. Challenges of Using a 3PL

Benefits:

- Scalability: Easily handle seasonal peaks without investing in more space or staff.

- Expertise: Leverage your partner’s knowledge of retail compliance, FBA prep, and international shipping.

- Wider Reach: Use a distributed warehouse network to get products closer to your customers and reduce shipping times. Challenges:

- Loss of Control: You can’t personally check on an urgent order. Mitigation: Choose a partner with a real-time portal that provides complete visibility into order status.

- Communication Gaps: You’re emailing an account manager instead of talking directly to a warehouse worker. Mitigation: Establish clear communication protocols and dedicated contacts.

Ready to transform your fulfillment into a competitive advantage?

Evolution Fulfillment provides the services, technology, and expertise your brand needs to unlock new growth. Partner with us and discover how seamless logistics can elevate your business. Contact Evolution Fulfillment Today